Special bearings for Pelješac Bridge in Croatia

The Pelješac Bridge, situated at the picturesque Croatian coast, will become one of the most impressive cable-stayed bridges. From 2022, it is supposed to connect northern Croatia with the country’s south, in particular the region of Dubrovnik. The bridge will be built in an earthquake zone; thus, the bearings must be capable of accommodating large movements and high horizontal forces. For this reason, half of the bearings have been installed vertically.

Media

The construction work at the current Pelješac Bridge – a first project was discontinued ten years ago – started mid of 2018 and is scheduled to be completed by the end of 2022. Building contractor is China Road and Bridge Corporation.

Pelješac Bridge has been political issue

The Pelješac Bridge has been a political issue for years. The south of Croatia can be solely accessed overland via the city of Neum that, however, belongs to Bosnia-Herzegovina. The new bridge featuring a width of a good 22 m will connect the Croatian mainland to the offshore peninsula Pelješac thus opening a complete overland route from the north to Dubrovnik. It is designed as an express highway with two traffic lanes in each direction.

Cable-stayed bridge with twelve pylons

The length of the bridge of 2,404 m will be subdivided into 13 different areas. The main bridge across the so-called Pelješac Canal is a cable-stayed bridge with twelve pylons. The five central span widths each amount to 285 m. The vertical clearance is 55 m.

16 vertically installed spherical bearings

In fall 2020, MAURER installed 32 spherical bearings in Croatia. The 16 bearings for bridge guidance in longitudinal direction presented a particular technical challenge. They must accommodate high horizontal loads of up to 19 MN and have to be installed vertically. In the process, it must be ensured that the sliding surfaces stay in close contact at any time. Wherever a gap arises, dust can ingress and compromise the sliding properties such as low friction. Moreover, this would result in wear that reduces the service life to five to ten years instead of at least 50 years as required.

Spherical bearings instead of pot bearings

Since the entire region is earthquake-prone, the bridge bearings must meet special requirements in terms of movability, durability, and load capacity. The planners envisaged two spherical bearings and two pot bearings each for the abutments and for six of twelve pylons in total.

“However, we succeeded in convincing the customer that spherical bearings are the only way to meet the technical requirements,” reported project manager Luca Paroli from MAURER. Spherical bearings are sliding bearings capable of accommodating arbitrary rotations in all directions without noticeable resistance via an internal spherical calotte joint and thus can transfer remarkably high forces restraint-free from the bridge deck into the substructure.

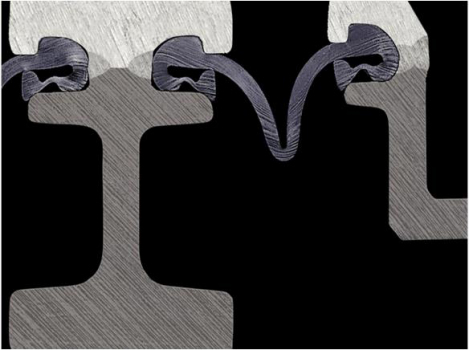

To this end, MAURER developed special bearings featuring disc springs in the core. The springs keep the sliding surfaces in close contact at any time with a force of approx. 500 kN in center position, in addition, they have been designed fatigue resistant – due to often occurring wind forces.

“This would not have worked out with pot bearings. In case of rotations, there would have been the risk of a gaping joint, resulting in significant wear and shortened service life due to a too rigid elastomeric element,“ explained Paroli.

Additional 16 spherical bearings, two for each pylon, were installed to accommodate vertical forces up to 33 MN. Since wind and earthquakes can result in uplift forces of up to 2 MN, the upper sections of the bearings are equipped with a cramp to prevent them from uplifting.

Furthermore, all bearings have to accommodate large, fast movements of up to ±1.3 m in case of an earthquake. That requires a bearing length of up to 3 m. The largest bearings feature a width of 1.2 m and a height of approx. 330 mm.

Important issue for bearings and joints: corrosion protection

The required corrosion protection also affects the design of the expansion joints. These flexible structural elements balance the temperature and seismic movements of the bridge deck of up to 1,400 mm versus the mainland. Concurrently, it is ensured that traffic can pass these expansion joints without restriction, irrespective of their displacement condition. The expansion joints are installed right-angled to the direction of traffic.

The two joints, each with 14 profiles, will be built by MAURER in hybrid design. In this case, hybrid means that the upper section of the steel profiles consists of stainless steel whereas the bottom section is made of structural steel, which provides high corrosion protection. The expansion joint will be delivered to Croatia in one piece since no welding work on the joint was allowed at the jobsite.

This means the expansion joint must only be lifted in position as one component by means of a crane and fastened to the structure, which will take no more than one to two days per joint.

MAURER SE

MAURER SE